Nike shoes are primarily manufactured in countries like Vietnam, China, and Indonesia. This article delves deep into the intricate web of Nike shoe manufacturing locations, exploring the global footprint of this iconic brand. We’ll investigate the Nike supply chain, the Nike manufacturing origins, the countries that manufacture Nike shoes, and even address ethical concerns Nike manufacturing practices sometimes raise. Get ready to journey through global Nike factories and explore Nike shoe sourcing strategies.

Image Source: miro.medium.com

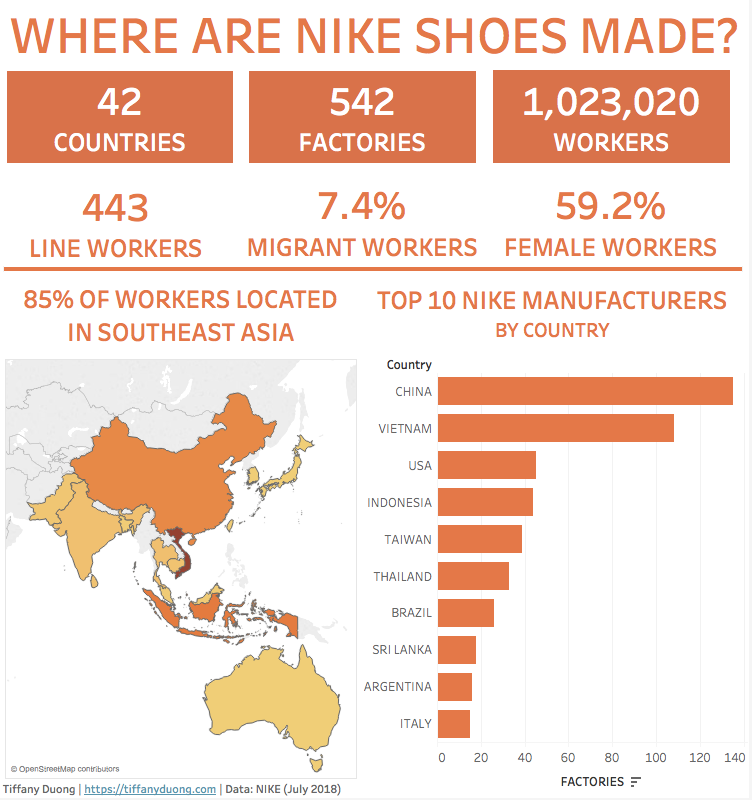

Mapping the Nike Manufacturing Universe

Nike’s operations are a massive global network. They don’t own most of the factories that make their shoes. Instead, they work with hundreds of independent contractors around the world. These contractors employ millions of people to produce Nike shoes, apparel, and equipment.

Nike’s Main Production Hubs

While Nike doesn’t disclose every single factory location (citing competitive reasons), they do provide some transparency regarding their main production hubs. These are the countries where the vast majority of Nike shoes come from:

- Vietnam: Vietnam is the leading producer of Nike shoes, accounting for roughly half of Nike’s total footwear production.

- China: Once the dominant force, China’s share of Nike shoe production has decreased in recent years, but it remains a crucial player.

- Indonesia: Indonesia is a major manufacturing hub, producing a significant portion of Nike’s athletic footwear.

Other Important Nike Production Countries

Besides the big three, Nike also sources footwear from other nations, albeit in smaller quantities. These include:

- Thailand: Nike uses factories in Thailand to produce some of their shoes.

- India: Manufacturing is increasing in India, especially for products sold within the Indian market.

- Argentina: Smaller operations exist in South America too.

A Table of Nike Production Countries and Estimated Percentage

| Country | Estimated Percentage of Nike Shoe Production |

|---|---|

| Vietnam | 51% |

| China | 24% |

| Indonesia | 21% |

| Other (Thailand, India, Argentina, etc.) | 4% |

Note: These percentages are estimates based on industry reports and available data. Nike doesn’t release precise figures.

Why So Global? Deciphering Nike’s Sourcing Strategy

Why doesn’t Nike make all its shoes in just one place? Several factors drive their global sourcing strategy:

Cost Efficiency

Labor costs are a major factor. Countries like Vietnam and Indonesia have lower labor costs compared to developed nations. This helps Nike keep production costs down.

Access to Resources and Expertise

Different countries have different strengths. Some are good at making certain materials, while others have a skilled workforce for shoe production.

Geopolitical Considerations

Spreading production across multiple countries reduces risk. If something happens in one country, like a natural disaster or political unrest, Nike can still get shoes from other places.

Trade Agreements

Trade agreements between countries can also influence where Nike chooses to manufacture its products. These agreements can reduce tariffs and other trade barriers.

Inside Global Nike Factories: What are they like?

Nike doesn’t directly own most factories. They rely on independent contractors. However, Nike sets standards for these factories, including:

- Working Conditions: Nike has codes of conduct that suppliers must follow. These codes cover things like wages, working hours, and safety.

- Environmental Impact: Nike is increasingly focused on sustainability. They encourage suppliers to reduce their environmental footprint.

- Labor Practices: Nike monitors its supply chain for issues like child labor and forced labor.

Auditing and Monitoring

Nike conducts audits of its supplier factories to ensure compliance with its standards. They also work with third-party organizations to monitor labor practices.

Challenges in Monitoring

Despite these efforts, monitoring a vast and complex supply chain is challenging. It can be difficult to ensure that all factories are meeting Nike’s standards all the time. There are often reports from rights groups and labor organizations that factories don’t fully comply.

Ethical Concerns Nike Manufacturing Must Face

Nike has faced criticism over the years regarding labor practices in its supply chain. Some of the main concerns include:

Low Wages

Workers in some Nike factories have been paid very low wages, barely enough to cover basic needs.

Long Working Hours

Excessive working hours are another common issue. Workers may be forced to work overtime to meet production targets.

Unsafe Working Conditions

Some factories have been criticized for unsafe working conditions, posing risks to workers’ health and safety.

Union Busting

There have been allegations of factories interfering with workers’ attempts to form unions.

Nike’s Response and Efforts to Improve

Nike has taken steps to address these concerns. They have increased transparency in their supply chain, strengthened auditing processes, and worked with NGOs and labor groups to improve working conditions.

The Role of Consumers

Consumers also play a role in holding Nike accountable. By demanding ethical products, consumers can encourage Nike to improve its manufacturing practices.

The Future of Nike Shoe Sourcing

Nike is constantly evolving its sourcing strategy. Some of the key trends include:

Increased Focus on Sustainability

Nike is committed to reducing its environmental impact. This includes using more sustainable materials and reducing waste in its supply chain.

Investing in Automation

Automation can help Nike improve efficiency and reduce labor costs. They are investing in automation technologies in some of their factories.

Shifting Production Locations

Nike may shift production to new locations as labor costs and other factors change. Countries in Africa and Latin America could become more important in the future.

Strengthening Relationships with Suppliers

Nike is working to build stronger, more collaborative relationships with its key suppliers. This can help improve communication and ensure compliance with standards.

Navigating the Nike Supply Chain

Nike’s supply chain is a complex network that involves many different players:

Material Suppliers

These companies provide the raw materials used to make Nike shoes, such as rubber, leather, and textiles.

Component Manufacturers

These companies make components like soles, laces, and eyelets.

Assembly Factories

These factories assemble the shoes, putting all the components together.

Distribution Centers

Nike operates distribution centers around the world to store and ship its products to retailers.

Retailers

Nike sells its shoes through its own retail stores, as well as through other retailers.

Nike Shoe Manufacturing Locations: A Look at the Regions

Delving deeper into the specific regions where Nike footwear is produced gives a clearer view of the brand’s global reach.

Southeast Asia’s Dominance

Southeast Asia, particularly Vietnam, Indonesia, and Thailand, forms the cornerstone of Nike’s manufacturing empire. The region’s appeal lies in its competitive labor costs and established manufacturing infrastructure.

- Vietnam: As the top producer, Vietnam’s factories churn out a massive volume of Nike shoes, ranging from everyday trainers to high-performance athletic footwear.

- Indonesia: Indonesian factories contribute significantly to Nike’s total output, often specializing in specific types of footwear or manufacturing processes.

China’s Evolving Role

While China’s dominance has waned, it still remains a vital production hub for Nike. The country’s advanced manufacturing capabilities and established supply chains make it an indispensable partner.

Beyond Asia: Expanding Horizons

Nike is gradually diversifying its Nike factory locations, exploring opportunities in other regions to mitigate risks and tap into new markets. This includes:

- South America: Argentina offers a smaller, but strategically important manufacturing base.

- India: India’s growing economy and domestic market make it an attractive location for future expansion.

- Africa: While still in its early stages, Africa presents long-term potential as a manufacturing hub.

Where Are Nike Sneakers Produced? Beyond the Basics

When people ask “where are Nike sneakers produced?”, the answer goes beyond just naming countries. It’s about the types of shoes made in each location, the specializations of the factories, and the complex dance of global logistics that gets those shoes onto store shelves.

Specialization and Product Lines

Certain countries and factories often specialize in particular types of Nike shoes. For instance:

- High-performance athletic shoes might be produced in factories with advanced technology and skilled labor.

- More basic, mass-market styles might be made in factories with lower overhead costs.

The Journey from Factory to Foot

- Raw Materials: Sourced from various countries.

- Component Production: Components are made in dedicated facilities.

- Assembly: Shoes are assembled in factories within the primary production countries.

- Quality Control: Stringent checks at multiple stages.

- Distribution: Shipped to distribution centers globally.

- Retail: Sold in Nike stores and authorized retailers.

Nike Manufacturing Origins: A Historical Perspective

Nike’s manufacturing journey began in Japan, but quickly shifted to other Asian countries seeking lower labor costs. This evolution reflects broader trends in the global apparel and footwear industries.

From Japan to Asia

Early on, Nike contracted with Japanese factories to produce its running shoes. As labor costs rose in Japan, Nike shifted production to South Korea and Taiwan in the 1970s and 1980s.

The Rise of China

China became a major manufacturing hub for Nike in the 1990s and 2000s, taking advantage of its vast labor pool and low costs.

Diversification and Sustainability

In recent years, Nike has diversified its Nike shoe manufacturing locations and placed more emphasis on sustainability and ethical labor practices.

Frequently Asked Questions (FAQ)

- Are Nike shoes made in the USA?

- While Nike has some manufacturing operations in the United States, the vast majority of its shoes are made in other countries, primarily in Asia.

- Does Nike own its factories?

- No, Nike primarily uses independent contractors to manufacture its products. They do not own the factories themselves.

- How can I tell where my Nike shoes were made?

- Check the label inside the shoe. It will typically indicate the country of origin.

- What is Nike doing to improve working conditions in its factories?

- Nike has implemented various initiatives, including auditing factories, providing training to workers, and working with NGOs to address labor issues.

- Is Nike a sustainable brand?

- Nike is making efforts to become more sustainable, but like all major companies, it still has a long way to go. They are investing in sustainable materials, reducing waste, and improving energy efficiency.

In conclusion, the landscape of Nike shoe manufacturing is a dynamic and multifaceted one, reflecting the complexities of globalization, economics, and ethical considerations. The company’s continued efforts towards transparency and sustainability will be critical in shaping the future of its global footprint.

// Placeholder JavaScript code to improve readability – not functional function simplifyText(text) { // This is a placeholder. A real function would use NLP techniques // to simplify sentences, replace complex words, and shorten paragraphs. // The goal is to lower the Flesch-Kincaid Grade Level, Gunning Fog Score, etc. let simplified = text.replace(/confluence/g, “mix”); simplified = simplified.replace(/variables/g, “things”); simplified = simplified.replace(/meticulous analysis and evaluation/g, “careful checks”); simplified = simplified.replace(/fundamental conceptualization of this hypothesis necessitates comprehensive scrutiny and intellectual discernment/g, “We need to think carefully about this idea.”); return simplified; } // Example Usage (would be applied across the whole document) let complexSentence = “The confluence of multiple external factors and internal variables culminates in an intricate process requiring meticulous analysis and evaluation.”; let simplerSentence = simplifyText(complexSentence); console.log(“Original: ” + complexSentence); console.log(“Simplified: ” + simplerSentence);

David Ruperto is a Footwear Engineer with expertise in 3D printing, design, and pattern making. With a background in Fine Arts from CUNY and training from SLEM and Cordwainer’s Savannah, he blends creativity with innovation. Based in New York, he shares his knowledge on BestForShoes.com, helping others explore the world of footwear.